EMBOSSED LABELS AND DEBOSSED LABELS

Embossing & debossing techniques involve the application of dies under pressure to transform two-dimensional paper or board into a 3D medium that is both irresistibly tactile and visually striking.

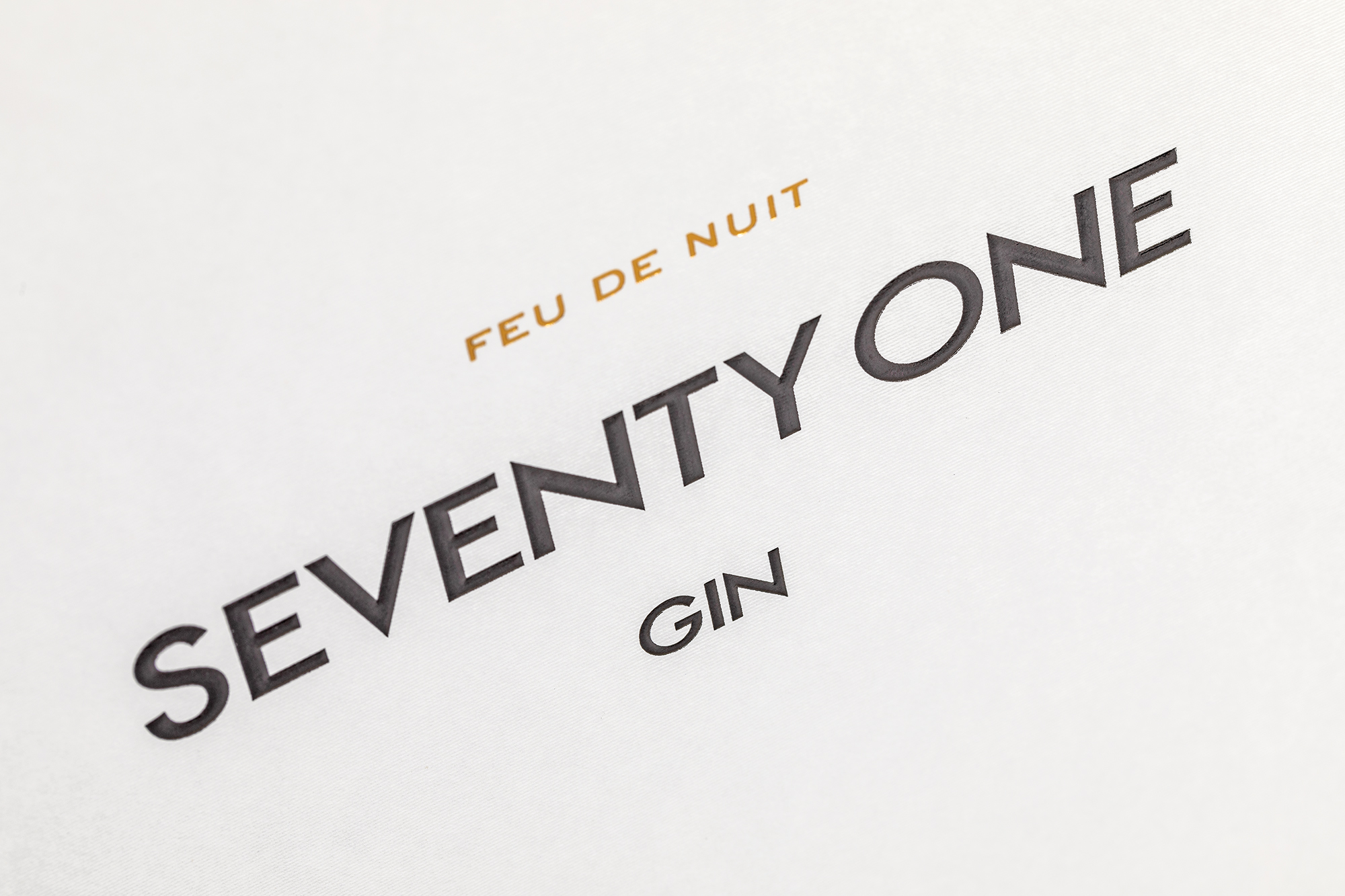

Embossing

Embossing involves the manipulation of a paper or card substrate to create a raised effect that lends depth and an extra tactile element to a 2d surface. Embossing is achieved using two metal parts – a male die and a female counterforce that come together with the substrate trapped in between.

There are different types of embossing dies available – flat dies, round dies and multi-level dies. We use some of the best dies available in order to achieve incredible, three dimensional effects. Embossing leaves a relief of the design on the reverse of the card or paperstock.

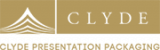

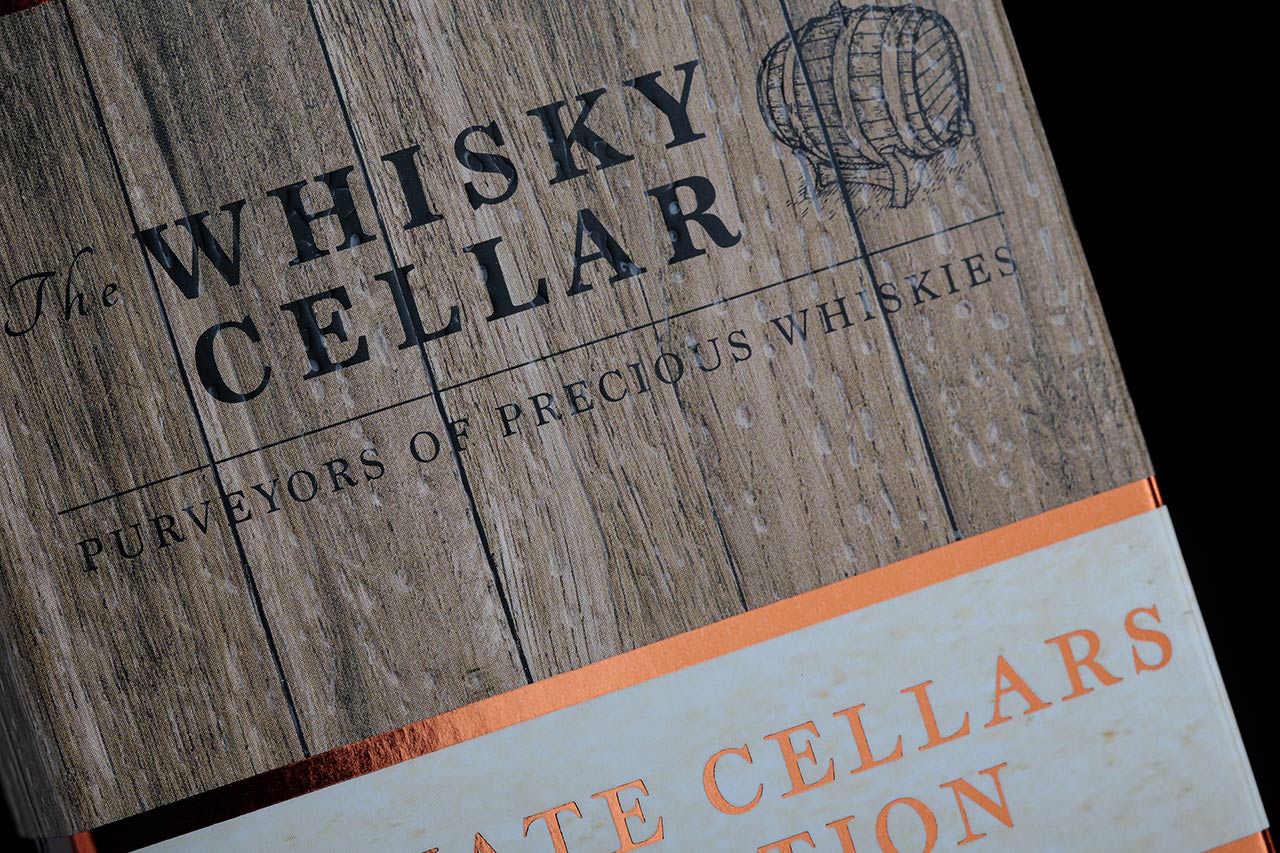

Debossing

Debossing is the opposite of embossing and involves pressing a design into the substrate to create a recessed effect, using a similar process to foil blocking. Debossing doesn’t usually leave an indentation on the reverse of the card if a heavy weight stock is used.

Both embossing and debossing can be done ‘blind’, without the application of print or foil, or combined with other print finishing techniques to create added impact.

Get in touch

With vast experience in luxury and bespoke presentation packaging, we’ve yet to find a design or manufacturing question our experienced team can’t answer. Contact us today to discuss your unique requirements further.